TRUSTED BY MEMBERS FROM

LEED GREEN ASSOCIATE, LEED AP BD+C AND WELL AP TRAINING SIMPLIFIED AND MADE EASY

WHAT IS LEED GREEN ASSOCIATE?

LEED Green Associate is a professional credential recognized worldwide that showcase understanding of green building principles and sustainable practices.

Statistics show that individuals who obtain the LEED Green Associate have increased their salaries, landed more clients and gained higher job positions.

Any professional in the building industry looking to learn more about green buildings to advance their career and standout should have the LEED Green Associate credential.

IS THE LEED GREEN ASSOCIATE WORTH IT?

INDUSTRY RECOGNITION

The LEED Green Associate credential is internationally recognized and respected in the green building industry. It signifies your expertise in sustainable building practices.

CAREER ADVANCEMENT

The LEED Green Associate certification can open doors to new career opportunities and advancement within the fields of architecture, construction, engineering, and sustainability.

ENVIRONMENTAL IMPACT

Certified professionals play a crucial role in promoting sustainable building practices. By obtaining this certification, you contribute to reducing the environmental impact of construction.

GLOBAL OPPORTUNITIES

The LEED Green Associate credential is applicable worldwide, allowing you to work on sustainable projects and contribute to environmental initiatives on a global scale.

SUSTAINABILITY ADVOCACY

By becoming a LEED Green Associate, you join a community of professionals dedicated to promoting green building practices, which is essential for a more sustainable future.

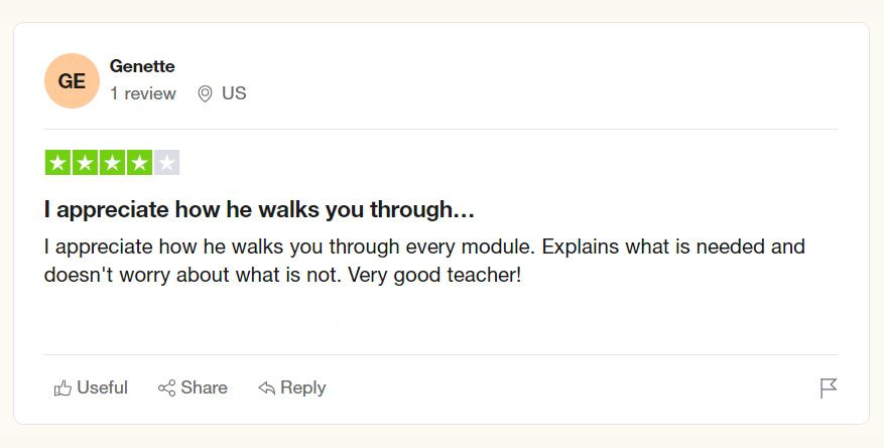

WHAT MAKES US UNIQUE?

SIMPLIFIED & CONDENSED LEED TRAINING

Forget about 30+ hour trainings, 800+ books and study guides.

100% PASS GUARANTEE

5000+ professionals passed. We guarantee a pass or your money back!

SECRETS TO FINDING THE ANSWERS

Sample questions will be done together in the training. Showcasing the secrets to find the correct answers with proven strategies.

ON-DEMAND INSTRUCTOR SUPPORT

Ask questions and schedule calls with the instructor.

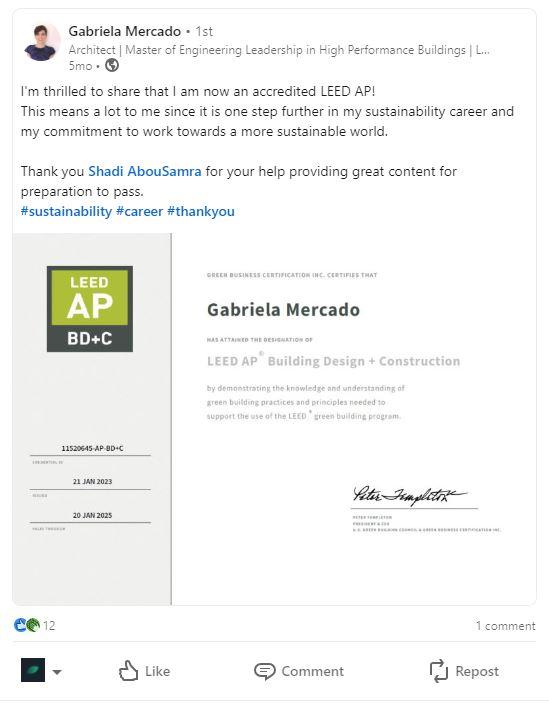

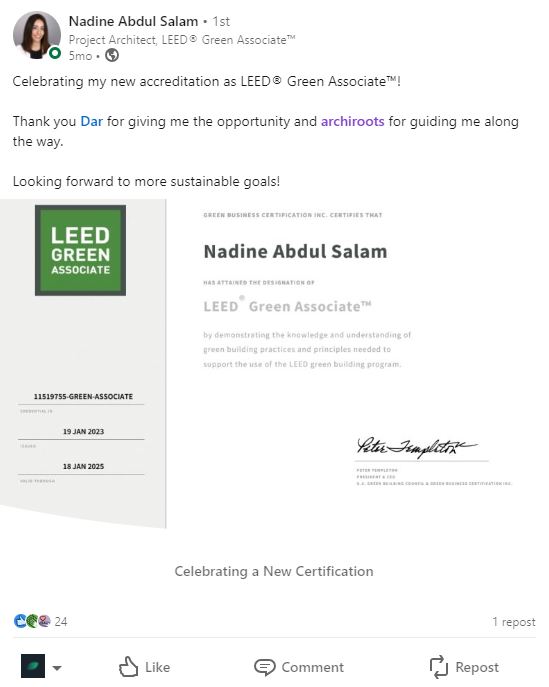

WHAT OUR STUDENTS ARE SAYING..

- 35% SALARY HIKE

- Ashraf Shaaban

Project Manager

- 47% SALARY HIKE

- Zeina Sawaya

Arch. Consultant

- 50% SALARY HIKE

- Omar Doughan

Operations Manager

- FIRST JOB

- Linda K.

Junior Architect

- 20% SALARY HIKE

- Daria Taeb

Project Manager

- Ashraf Shaaban

Project Manager

- Omar Doughan

Operations Manager

- Zeina Sawaya

Arch. Consultant

ABOUT US

Archiroots is an international education company helping professionals earn LEED Green Associate, LEED AP BD+C, and WELL AP certifications in weeks instead of months.

Making AEC education more widely accessible, affordable and guaranteed results. Connecting thousands of individuals to the right study material with no fluff or confusing information that wastes professionals valuable time.

Breaking down months of content in a matter of hours. The LEED Green Associate which typically takes 2 to 3 months to prepare can be earned in a matter of 2 weeks or even less.

HOW TO BECOME A LEED GREEN ASSOCIATE?

Becoming a LEED Green Associate is a straightforward process, there is no requirements, no specific discipline or experience needed.

You only need to pass the LEED Green Associate exam to earn the certification. First thing you need to do is learn the green building concepts, LEED process and all LEED categories like “Energy & Atmosphere” and “Water Efficiency”. Next, take as many LEED Green Associate Practice Exams as possible to make sure you are familiar with the exam format.

When your ready, head to USGBC and register for the LEED Green Associate exam. You will earn a USGBC ID after registration, which you will use on another website “Prometric” to schedule a time, date and location or even online through “ProProctor”.

All of the above will be discussed in depth in the LEED Green Associate exam prep course.

WHO WILL BENEFIT FROM OBTAINING THE LEED GREEN ASSOCIATE?

The LEED Green Associate course benefits individuals in the architecture, engineering, construction, and sustainability sectors. Here’s who can benefit from this course:

• ARCHITECTS AND DESIGERS

Architects, Interior Architects, Interior Designers can gain the skillset and knowledge of sustainable design principles.

• ENGINEERS AND BUILDING PROFESSIONALS

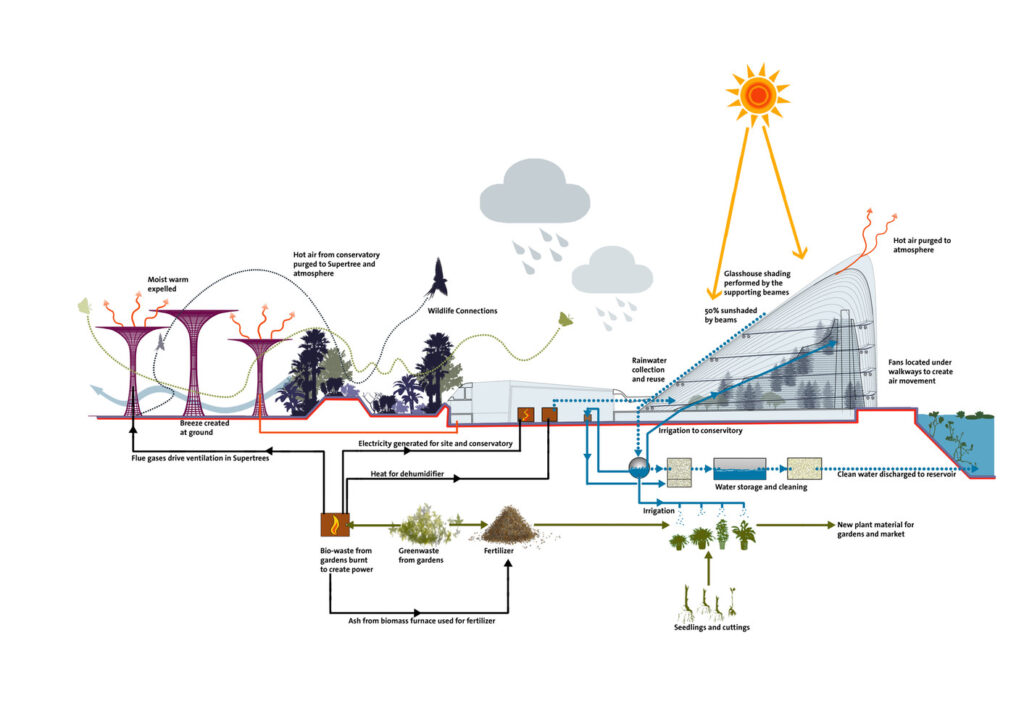

Mechanical Engineers, Civil Engineers, Electric Engineers, Chemical Engineers, Contractors, Construction Managers and Facility Managers would gain knowledge in fields like commissioning, low ozone depletion refrigerants, reducing heat islands and erosion.

• ENVIRONMENTAL CONSULTANTS

Professionals in or looking to become sustainability consultants to help energy model and streamline Green building certification processes. To consult professionals in the building industry to transform their projects to reduce impact on the environment.

• REAL ESTATE PROFESSIONALS

Real estate agents, developers, and property managers can leverage their LEED knowledge to market and manage sustainable properties, attracting environmentally conscious clients

• STUDENTS AND GRADUATES

Students pursuing degrees in the buidling industry like architecture or engineering can jumpstart their careers by obtaining the LEED Green Associate credential, making them more attractive to potential employers and would benefit from a large discount on the official exam.

• GOVERNMENT EMPLOYEES

Individuals working in government agencies responsible for building codes and regulations can gain insights into sustainable building practices and contribute to the development of greener communities.

• SEEKING CAREER ADVANCEMENT

Anyone looking to advance their career or shift into the growing field of sustainable design and construction can benefit from the LEED Green Associate credential as it enhances job prospects and earning potential.

LEED GREEN ASSOCIATE STATISTICS

OUR MOST POPULAR ARTICLES

FAQ

Eligibility for the LEED Green Associate exam is open to anyone interested in sustainable building and design. There are no specific prerequisites or prior experience requirements.

You can prepare for the LEED Green Associate exam through our LEED Green Associate exam prep course then take on our practice exams.

The LEED Green Associate exam is administered at approved testing centers worldwide. You can find a testing center near you by visiting the Prometric website.

Mainly the LEED categories are what’s covered in the official exam. Which are Location and Transportation, Sustainable Sites, Energy and Atmosphere, Water Efficiency, Materials and Resources, Indoor Environmental Quality.

The exam consists of 100 multiple-choice questions and is typically completed within two hours. It is a computer-based exam.

The passing score for the LEED Green Associate exam is 170 out of 200. It’s important to note that the exam is scaled, so the exact number of correct answers required may vary slightly.

Becoming a LEED Green Associate can enhance your career opportunities, demonstrate your commitment to sustainability, and provide you with the knowledge and skills to contribute to environmentally responsible building practices.

There are two available methods for completing the LEED Green Associate exam. You can choose to take the exam either in person at a Prometric testing center or virtually from the comfort of your preferred location via the ProProctor application, which enables remote online proctoring.